Market report

Painter's Insights

Explore the impact of sanding robots on painting jobs. Are they enhancing productivity or just a passing fad? Read our comprehensive review to find out.

Blogs I published 10 November 2025 I Dirk Hoogenboom

Sanding Robots for Painters: Hype or Real Jobsite Gains?

Ask a painter what part of the job they’d gladly hand off if they could, and most will answer without thinking. With the dust, noise and endless repetition – arms up, mask on, vacuum roaring – it’s no wonder most would reply sanding. The kind of work that leaves your shoulders sore and your patience thin. What’s more, one of the few parts of the trade that hasn’t meaningfully changed in decades. Tools got lighter and vacuums got better, but the principle stayed the same – a person, a pad and a surface. Every painter has done it, nobody misses it.

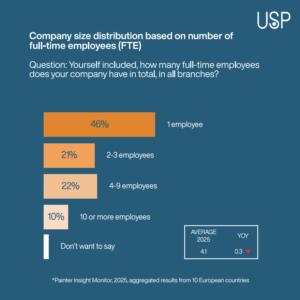

Now, that might finally change. Across Europe, sanding robots are starting to move from novelty prototypes to jobsite tools. What started as industrial automation in automotive finishing is trickling down into building renovation and interior trades. In our latest Painter Insight Monitor, sanding robots are ranked as one of the top four most-watched innovations among European painters, ranking just behind exoskeletons. Almost all painters (about 88%) already know about sanding robots, and roughly 31-35% say they’d seriously consider using one. That’s a big number, especially for a trade that moves cautiously on new tech.

Why Sanding Sinks Time

Painting looks simple to outsiders – pick a color, roll it on, and that’s about it. But most of the work happens before a brush even touches the wall. Surface prep eats 15-30% of total hours, sometimes 40% on older buildings. It’s dusty, awkward and physically brutal, especially on ceilings and stairwells. It’s also where mistakes show. Skip prep, and the finish shows immediately; do it right, and no one notices. It’s invisible labor that wears people down and rarely gets appreciated.

So when a tool comes along that can take over that part, painters listen. Not because they want to sit around while a robot does their work for them, but because they’d rather save their shoulders for something that actually needs their skill.

What These Robots Actually Do

It’s not a roboticised Hollywood stereotype, there’s no metallic workers with arms and a grudge. They’re compact, mounted machines that move methodically over surfaces, guided by sensors and suction.

They come in two main forms:

- Mobile wall/floor robots – self-driving or guided systems that sand plaster, drywall or façades

- Robotic arms or mounts – attachable to scaffolding or tracks, programmed to handle ceilings or repetitive panels

Most systems use:

- LIDAR or camera mapping to read the wall and plan their path

- Motorized sanding heads with adjustable torque and pressure

- Integrated dust extraction that hooks into standard vacs

- App-based controls for setting area, grit, and pattern

The leading names – Mirka’s AIROS, Robot At Work, Festool’s automated platform – are already running pilots in Germany, Sweden and the Netherlands. The performance looks quite solid:

- 2-3× faster on large flat areas than manual sanding

- 40-50% shorter prep times on full renovation projects

- Up to 60% less airborne dust when paired with extraction

- Painters report roughly half the usual fatigue at the end of the day

Output data shows that a single unit can cover 250–300m² a day, the same as two painters doing nothing but prep.

How They Could Fit into Workflows

Sanding robots won’t replace painters, but become part of the crew, as tireless apprentices that never complain or take breaks. In practical terms, the workflow might look like this:

- Setup: The painter scans or inputs the room layout

- Calibration: Robot maps surface geometry

- Operation: Robot performs base sanding while the painter preps corners, edges and checks quality

- Finish: Painter fine-sands where necessary and moves the robot to the next room

Early adopters report a productivity gain of 25-40% and dust exposure reduction of up to 90% with integrated vacuum systems. It’s not about soundbites.

Where the Interest Comes From

The Monitor shows sanding robots attract 31-40% interest overall among painters across Europe, with appetite peaking in Italy, Spain and France (all three at 21%), Poland (19%) and Portugal (23%).

It’s lower in northern markets, where smaller job sizes and price sensitivity limit experimentation. According to the Monitor:

- Interest is strongest in Poland, Spain and France, whose painters consider sanding robots more helpful

- Belgium and Portugal are close behind; curiosity is high, but costs are a barrier

- Among Millennial and Gen-X painters, interest runs above 30%, but older painters’ disinterest sits at around 57%

So it’s not resistance; it’s economics. The people open to using them are the ones still planning to be on-site in 20 years’ time. They already feel the toll of manual prep and they’re realistic about the labor market. If you can’t hire more hands, there’s smarter ways to stretch the ones you’ve got. And they’re asking for speed, a dust-free, ergonomic experience through a long-neck “giraffe” sander.

The Business Case

A good robot costs 8.000-12.000 EUR, higher-end ones double that. On the surface, that sounds steep. But consider how much time sanding burns. If it eats a quarter of total labor and automation cuts that in half, the math flips quickly.

Let’s say a mid-sized firm turns over 500.000 EUR in labor. Ten percent time saved on prep is 50.000 EUR a year, so the machine pays for itself in under two years. That’s before you count the softer savings like fewer sick days, less turnover and less burnout.

That’s why leasing is taking off. Distributors in the Nordic regions now offer rental packages for 150-200 EUR per week. Use it when you need it, return it when you don’t. The same way scaffolding or sprayers are rented. For solo painters, that’s the only viable entry point. You don’t buy a sanding robot for a single villa repaint, but you might rent one for a big commercial job to spare your shoulders.

Feedback from early pilots is surprisingly straightforward. Crews say the learning curve is steepest in the first ten minutes – learning the controls, trusting the sensors – then it just becomes background noise. You’re still working, just differently. Instead of sweating with the sander, you manage the machine, prep the next area, check the finish, keep things moving.

Painters who used to finish a ceiling and need a break now just switch walls. The rhythm changes; the strain drops. The job gets cleaner, faster, quieter. It’s not glamour, it’s just practicalities.

Shifting Attitudes

Painters are practical people. If something works, it stays. If it breaks or slows you down, it’s gone. Exoskeletons earned their spot because they make painters feel better at the end of the day. Sanding robots could earn it by keeping everyone cleaner and quicker without sacrificing finish quality.

Older painters are warming up once they see the numbers. The initial reaction – “I don’t need a robot to do my job” – fades fast after a single demo. Most walk away thinking they could have been using that ten years ago.

There’s also the image factor. Younger tradespeople are proud to use advanced tools. It helps with recruitment too; students seeing robotics on-site start seeing painting as modern, not outdated. That matters more than anyone admits.

Health and Safety Payoff

Everyone in the trade talks about fatigue, but the numbers show how deep the problem runs. EU-OSHA surveys find:

- 60% of painters report chronic shoulder or neck pain

- 45% deal with lower-back issues

- 1 in 5 leave the trade early because of musculoskeletal problems

Most of that comes from repetitive overhead work and vibration. Sanding hits both simultaneously. Every hour you take it off someone’s hands is an hour less risk of long-term injury.

The Practical Barriers

Still, it’s not all smooth sailing.

- Price: A 10.000 EUR robot is hard to justify for a one-man business; expect adoption first among mid-sized firms with stable pipelines

- Training: You can’t just plug and play; miscalibration can gouge plaster or chew through pads, so most models need some know-how

- Maintenance: Sensors need cleaning, filters clog and software needs updates, so know that not all painters want to deal with that

- Versatility: Robots excel on big flat walls; awkward angles and trim still need people

- Cultural perception: Automation still triggers skepticism on cheapened craftsmanship, even if they make the work safer and faster

But all that’s fine. It’s not meant to cover the full 100%. The sweet spot is taking the dull, repetitive 70% and freeing painters for the parts that still require skill and finesse.

Early Trials and Real-World Use

So the promise is big. But how’s it actually performing?

Sweden

Ceiling sanding pilots with Skanska show 40% lower EMG muscle activity and no drop in surface quality. Crews complete the same area with less fatigue.

Portugal

Independent painters are keen but cautious. Around 70% cite cost as their only obstacle. Distributors testing shared-rental models say demand spikes whenever they demo live.

Netherlands

Public-sector renovation tenders increasingly ask for “dust-controlled sanding” as a minimum spec, pushing automation indirectly.

Those numbers line up with what happened when spray systems hit the market twenty years ago. First curiosity, then demos, then rapid normalization.

The Bigger Picture

If sanding robots deliver what trials promise, they’ll quietly rewrite how jobs are scheduled and staffed. Imagine prep teams cut in half, painters starting work sooner and entire sites finishing a day or two earlier; project management changes shape in real-time.

It also reshapes tool markets. A 5% adoption rate across Europe’s 1.2 million painters means a potential 150-200 million EUR market within five years. That’s enough to push every major tool brand into robotics. Expect lower costs in some five years’ time and probably consumer-grade models not long after.

The ripple effect goes further:

- Vocational schools start teaching robotics as standard

- Suppliers shift from selling tools to renting systems

- Painters extend their working lives instead of retiring early

That’s a chain reaction worth the watch.

Looking Ahead

Painters don’t need miracles. They need tools that make the hard parts bearable. If exoskeletons gave painters endurance, sanding robots could give them relief. They’re not here to change what painting is, just some faith in making it into something you can keep doing for longer, with cleaner lungs and a better night’s sleep.

So give it five years. If the current pace continues, sanding robots will be as normal as sprayers – not replacing painters, just reshaping their workflow. Expect early mass adoption spreading across the continent as the culture, workforce and rental access reshuffle. By 2030, “manual sanding” might sound as outdated as mixing paint by hand.

For now, the takeaway is simple; automation in painting doesn’t mean less craftsmanship. It means fewer broken shoulders and fewer 12-hour prep days.