Market report

Millennial Painters Want Superpowers

Delve into the world of European painting, analyzing the balance between speed and downtime in each country. Uncover trends that shape the art scene.

Blogs I published 13 October 2025 I Dirk Hoogenboom

Painting in Europe: Speed vs. Downtime, Country by Country

Painters have always had strong backs and steady hands. That’s the nature of the job. But even the toughest of shoulders have their limits. After decades of rolling, sanding and cutting in ceilings, fatigue builds up like layers of paint. That’s why when the new generation of painters starts talking about “tech,” they don’t mean apps or marketing tools, but rather – something far more practical. They’re talking about physical help. Real, mechanical help. And that’s where exoskeletons come into the conversation.

Across Europe, painters are becoming early adopters of wearable robotics, tools designed not to replace people, but to give them endurance, strength and better posture. What sounds – or, indeed, still sounds – like a videogame phrase is becoming a sought-after and familiar reality on-site.

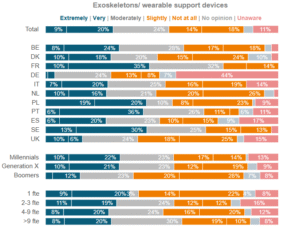

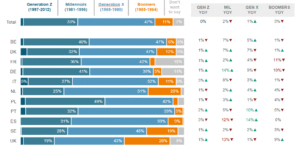

According to our 2025 Painter Insight Monitor, exoskeletons currently rank as the #1 most interesting innovation among painters out of the four tracked technologies (outranking digital color tools, connected devices and automated sprayers). The strongest interest comes from France, Portugal, Sweden and Poland, with enthusiasm shared by both Millennials and Gen-X.

Meaning that a trade defined by physical endurance is finally finding technology that doesn’t just save time – it saves the body. Here are the specifics.

The Four Technologies Painters Are Watching

Before looking at exoskeletons, here’s what our research says painters are tracking:

- Exoskeletons – wearable support systems that reduce strain in arms, shoulders and back

- Smart connected tools – devices that monitor usage and maintenance (e.g. sensor-based sprayers and paint meters) at 40-ish% interest, mostly mid-sized firms

- AI color recommendation software – digital tools helping clients visualize outcomes; 35–38% interest, especially among design-oriented painters

- Automated paint sprayers/robotics – mainly interesting to larger firms or industrial painters; 25–30% interest

Among these, exoskeletons dominate in interest by a wide margin. In most European countries, over 50–60% of painters expressed positive interest in them. And crucially, not as an interesting novelty but as a potential investment. While the other technologies speak to efficiency or creativity, exoskeletons speak, in a way, to bare survival – to staying in the trade longer, healthier and with fewer injuries. They have an immediate, tangible benefit, don’t need Wi-Fi, training or digital literacy. You wear it and feel the difference day-of.

What an Exoskeleton Actually Is

Before the sci-fi imagery runs amok – they may sound like a robotic suit, but aren’t really. There are no motors or hydraulics involved. Think of them like a backpack rig or belt of springs, because most painting models use springs, tension bands or elastic supports to offset the force needed to keep your arms overhead. In practical terms, an exoskeleton is a mechanical support frame that fits over the painter’s body – most often the upper body and arms – and is designed to redistribute physical load.

It’s essentially a lightweight shoulder harness that takes some of the weight off your muscles when you roll ceilings for hours. An average unit weighs somewhere between 2.5–5 kg, is made from aluminum or carbon fiber and currently costs from €1,500–€3,000 per device, depending on the specific model and support zones.

Companies like Skelex (Netherlands), Ottobock (Germany), and Comau (Italy) are already piloting models on construction and industrial painting sites. And the results are striking:

- Muscle activity reduction – up to 30-40% lower shoulder load, measured by EMG studies from the Fraunhofer Institute (2022)

- Pain reduction – workers report up to 50% less perceived fatigue during sustained overhead work

- Productivity stability – same output over longer days without drop-off in precision

A painter who can work comfortably six hours overhead instead of four gets more done or stays in the trade five years longer. It looks like simple math, because it is.

Why Painters Are Paying Attention

The Monitor shows that exoskeleton interest is both demographic and geographic.

- France: 65% of painters say they’re interested or “very interested” in exoskeletons

- Portugal: 60–62%

- Sweden: roughly 58%

- Poland: about 55%

- Other markets (Germany, Netherlands, Italy) peak at around 40–45% interest

As for the generational breakdown, the story is even clearer:

- Millennials (25–42 years): 68% interest

- Gen-X (43–58 years): 59% interest

- Boomers (59+): only 31% interest

This pattern makes sense. Younger painters – especially Millennials running solo or two-person businesses – are physically feeling the strain earlier because they often work faster and longer hours. To them, exoskeletons aren’t gimmicks but long-term insurance.

What’s Driving Adoption

1. An Aging Workforce

Painters in Europe average on 49 years old, and stuies show that shoulder injuries are among the top 3 causes of early retirement in manual trades. Exoskeletons seem to promise an extended career by making physically intense tasks sustainable longer.

2. Ergonomic Pressure

According to EU-OSHA data, over 60% of construction painters report chronic shoulder or neck pain and 45% report lower back issues. Fatigue means slower work, more mistakes, serious injuries and eventual dropouts. Exoskeletons are being trialed as a direct fix.

3. Efficiency with Precision

Unlike automation, exoskeletons don’t replace skill, but amplify it. Painters maintain control, dexterity and finish quality – they just get things done with less strain.

4. Technology Maturity

The hardware has improved. Early exosuits were bulky and restrictive. The new generation is lightweight, washable and compatible with safety gear.

5. Regulation and Awareness

EU’s Horizon 2020 program funded more than €80 million in wearable robotics R&D between 2018-2024, accelerating product maturity. Occupational health agencies now recognize exoskeletons as legitimate ergonomic aids, not experimental augmentation.

Early Case Studies and Real Trials

France (Bouygues Construction) – In pilot programs using upper-body exoskeletons on façade work, painters reported:

- 30% reduction in shoulder discomfort

- 25% increase in consistency of pace across shifts

- 9 out of 10 participants said they’d “keep using it” if available

Sweden (Skanska pilot) – Painters using passive shoulder exoskeletons for ceiling work showed:

- 40% less EMG activity in shoulder muscles

- No decline in precision or coating uniformity

- Improved perception of safety and endurance

Portugal (independent firms) – The barrier is price, not skepticism. When asked why they hadn’t yet tried one, 72% cited cost, not lack of trust. That’s where suppliers and rental models can make a difference.

Poland is a frontier case: vocational schools have started demonstration modules on wearable ergonomics, which could make adoption generational or preventive rather than reactionary.

Why Millennials Lead Adoption

Plain and simple? Mindset. Millennial painters grew up with wearables – smartwatches, fitness trackers, digital tools, so strapping on tech doesn’t feel like an unafamiliar stretch. Especially when it delivers results.

They also face a harsher reality: more competition, more ergonomic pressure and less job security. Many run solo operations and can’t afford to lose weeks to injury. That’s why 68% of Millennial painters express interest, compared to an ostensibly smaller third of Boomers. They see tech as leverage, a way to gain what used to come from experience and stamina.

And because Millennials are already shaping the future of the trade – starting small firms, working independently and driving social media visibility – they’re also the ones normalizing exoskeletons as part of a “modern painting get-up.”

Barriers to Adoption

Innovation always comes with friction. For exoskeletons, it consists of a mix of cost, culture and context.

- Cost – At €1,500–3,000 per unit, it’s a major expense for solo painters, so manufacturers are looking into rental or pay-per-use models to break the barrier

- Comfort and usability – If it’s too hot, heavy or restrictive, painters ditch it. Next-gen suits now feature ventilation panels and quick-release harnesses to improve comfort

- Perception – Some painters still equate wearables with weakness, which translates to something like “if you need a robot to paint, maybe you shouldn’t be painting.” But that stigma will fade as more firms hop on

- Training gap – A misfit harnesses or wrong tension settings can actually increase fatigue, so proper use requires a short onboarding process

What It Means for the Trade

For everyone connected to painting – from professionals to suppliers to policymakers – exoskeletons signal a paradigm shift in how we think about “tools.”

For Painters:

- They’re no longer just relying on strength. They’re buying stamina

- Think of it like PPE 2.0 – gear that protects muscles, not just skin

- Early adopters can cut fatigue by up to 40% and extend career longevity

For Employers and Mid-Sized Firms:

- Reduced sick days and injury claims

- Better job completion rates on repetitive ceiling or façade work

For Suppliers and Manufacturers:

- The opportunity is massive. If even 10% of Europe’s 1.2 million professional painters adopt exoskeletons in the next five years, that’s a €180–300 million potential market

- The key will be affordable, ruggedized models and rental access through distributors

For Vocational Educators and Trainers:

- Integrate ergonomics and wearable tech into curricula

- Teach the “why,” not just the how, behind body mechanics

- Make it part of professional identity – smart, safe, modern

The Road Ahead

Adoption will start where it always does; with early adopters and visible champions. Expect France and Sweden to take the helm, followed by Portugal and Poland where interest is already high. Expect new product generations to drop costs below €1,000 per unit by 2027. Expect new insurance incentives, as occupational health systems start recognizing exoskeletons as valid prevention tools. And expect to see them on more sites, quietly changing what it means to be efficient, healthy and sustainable in a trade that’s been grinding for generations.

Conclusion

In short, young painters want superpowers, and for the first time, tech is actually trying to respond. Granted, skeptics will say they don’t need robotic suits. But painters could reply that they have far less to do with robotics, and overwhelmingly with longevity. When 60% of the over-45s report chronic pain, when the average age is nearing 50 and when recruitment is slowing – there’s clearly wiggle room and a need for change.

Exoskeletons aren’t a magic fix – they won’t solve the labor shortage or change the impact of weather on jobs at hand, but they’re a confident step forward in a trade that rarely gets technological breakthroughs. They bridge a critical gap between traditional craftsmanship and 21st-century ergonomics and show that innovation doesn’t always mean digital transitions – sometimes it’s mechanical, resilience-centered, human. In a trade where endurance is everything, that’s a solid pitch.